The water source for the chemical water system of a power generation company in Hunan Province is lake water. After being treated by a high-density sedimentation tank and a filter, the water enters the ultrafiltration system. The ultrafiltration system is designed with a capacity of 2×210 t/h (net output) and a recovery rate of ≥90%. The process flow is as follows:

High-density sedimentation tank → Industrial water tank (existing) → Industrial water pump → Filter → Filtration water tank → Filtration water pump → Self-cleaning filter → Ultrafiltration device → Ultrafiltration water tank.

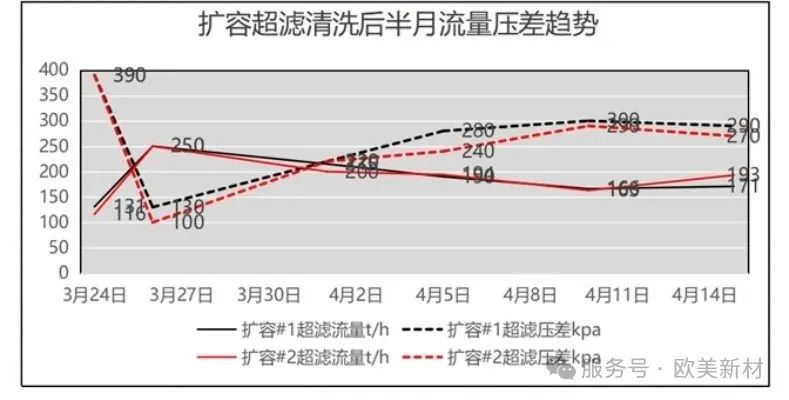

In 2021, 100 pieces of iXP-8080 ultrafiltration membranes were replaced. They have been in operation for over 3 years so far. Recently, the ultrafiltration system has been facing issues such as high operating pressure, large pressure difference, rapid decline in water production flow, incomplete recovery after cleaning, and a severely shortened cleaning cycle to less than 20 days. The data comparison before and after cleaning is as follows:

According to the data before and after cleaning, the water production flow of Ultrafiltration Unit #1 is only 131 t/h, which is approximately 60% of the designed water production. Meanwhile, the pressure difference reaches as high as 3.9 bar. Although the water production recovers after cleaning, the operating pressure difference still remains at 1.3 bar. This indicates incomplete cleaning, and a thorough analysis of the ultrafiltration fouling situation is required.

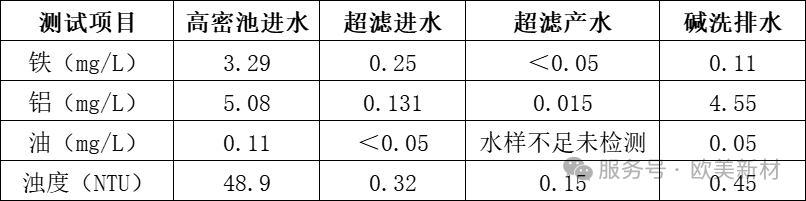

Through communication, it was learned that the acidic cleaning solution used in previous cleanings would appear dark yellow to reddish-brown. Combined with the situation where the pressure difference rises rapidly after ultrafiltration fouling, water production decays quickly, and conventional chemical cleaning is incomplete, it is initially judged that the pollutant is iron. On-site water samples were collected for water quality analysis, and the results are as follows: