Project Background

For a wastewater reuse project of a rubber product factory in Thailand, the B/C ratio in the wastewater is extremely low, indicating poor biodegradability. The wastewater contains a large amount of non-biodegradable synthetic rubber components (such as styrene-butadiene rubber, chloroprene rubber, etc.) and polymer additives, making the ultrafiltration system highly prone to mechanical fouling during operation.

The project adopted 40 Ochemate® iXP-8080 ultrafiltration membranes, divided into two systems, each with a water production capacity of 80 m³/h. They were put into use in July 2019 and have been in operation for nearly 6 years so far.

The process flow is as follows:

Raw rubber wastewater → PAC/PAM dosing → Coagulation sedimentation tank → Intermediate water tank → 200µm self-cleaning filter → Ultrafiltration → Ultrafiltration product water tank → Activated carbon filter → 5µm security filter → Reverse osmosis → Effluent reuse

02 Problem Description

Due to the large amount of suspended colloidal particles in rubber wastewater, the treatment effect of coagulation sedimentation is limited, leaving the ultrafiltration system at high risk of mechanical fouling. In July 2020, the ultrafiltration system suffered severe fouling: water production dropped sharply to less than 40 m³/h, and the operating pressure rose rapidly from less than 1 bar to over 2.0 bar. However, the recovery effect after chemical cleaning was not obvious.

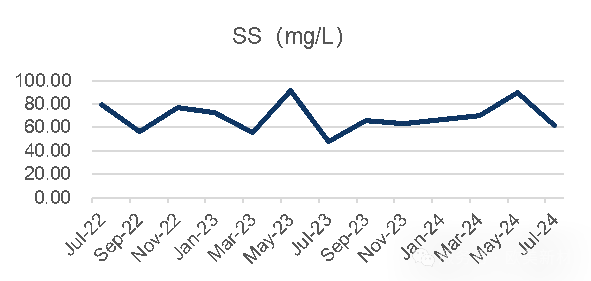

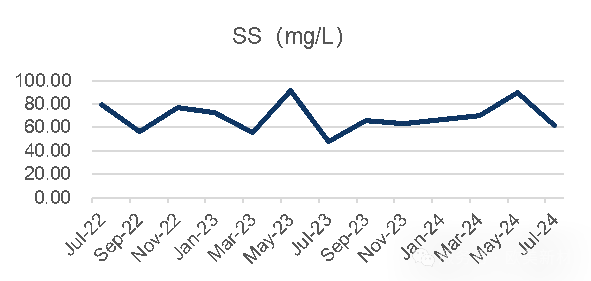

Water quality testing of the ultrafiltration feed water showed: BOD of approximately 10 mg/L, COD of approximately 60 mg/L, and a B/C ratio of 0.17, indicating extremely poor biodegradability. Suspended solids remained at around 60 mg/L all year round, and the ultrafiltration feed water still contained a large amount of non-biodegradable synthetic rubber particles, leading to mechanical fouling that could not be reversed by conventional chemical cleaning.

03 Solution and Effect

Based on the water quality and ultrafiltration fouling situation, Oumei New Materials formulated a special cleaning and recovery plan, which combined extensive air scrubbing with special cleaning agents for restoration.

Specific plan: During chemical cleaning, surfactants were used to activate pollutants; meanwhile, a large amount of air scrubbing was applied to peel off contaminants.

Specific measures: Before chemical cleaning, compressed air with an air source pressure of 1.0~1.5 bar was used for air scrubbing. The air intake per membrane was controlled at 10 Nm³/h, with each air injection lasting 20~30 seconds, followed by a 20-second pause, and then another 20~30 seconds of air injection. This cycle was repeated 4~5 times, after which water was drained to observe the discharge of rubber particles. After draining, backwashing was performed, followed by another round of air scrubbing until no obvious colloidal particles were observed in the drained water. Chemical cleaning was then carried out, with the above air scrubbing steps added during the soaking process to enhance the cleaning effect. After soaking, high-flow circulation cleaning was performed, followed by backwashing of the ultrafiltration system to restore it to operating status, and the cleaning effect was observed.

Recovery result: After cleaning according to the customized plan, the ultrafiltration system returned to its initial operating state.

04 Operation Adjustment Suggestions

Based on the above situation, our company suggested that the customer increase the air scrubbing intensity during operation: adjust the air intake pressure to 1.0~1.5 bar, increase the air intake to 10 Nm³/h, and set the backwash cycle to 30 minutes. By increasing air volume and frequency of air scrubbing, the occurrence of mechanical fouling in ultrafiltration was reduced. Up to now, the customer has operated according to our plan without further severe mechanical fouling, and both water production and product water quality have reached the design values.

05 Conclusion

Ochemate® iXP ultrafiltration membranes have undergone nearly 100,000 times of high-intensity air scrubbing over nearly 6 years, fully demonstrating their durable and robust characteristics, which escort the long-term stable operation of the system.